ICMmonitor on-line partial discharge monitor

PD monitoring according to international standards

Perform permanent partial discharge on-line measurements that fully comply to the IEC 60270 standard

Helps you to make the right decisions

The acquired measurement data is a valuable piece of trending information for a reliable forecast and prevention of unexpected outages

Available for indoor or outdoor installations

The five available housing versions of the acquisition unit adapt the system to the intended indoor or outdoor environment.

High modularity

Configure your ICMmonitor with a wide range of optional features and accessories to fulfil your specific needs

About the product

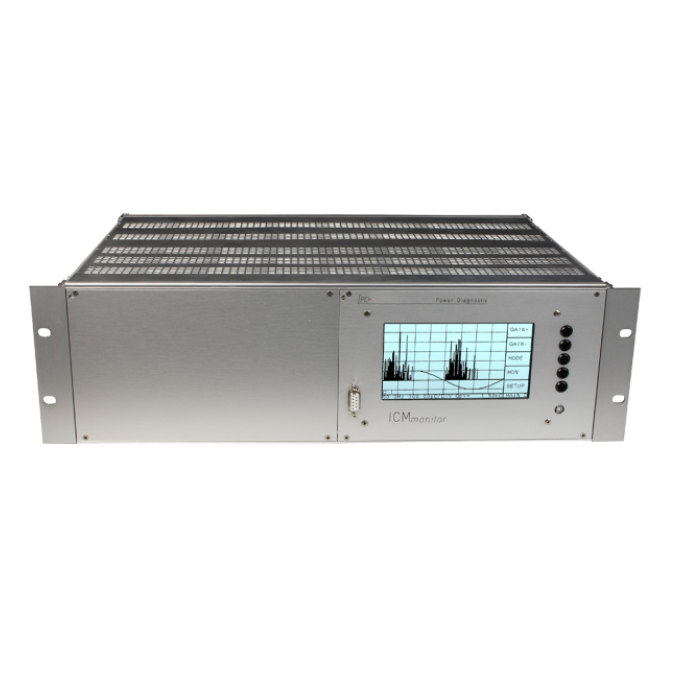

The ICMmonitor on-line partial discharge monitor continuously monitors the condition of the insulation system of your medium and high voltage (MV and HV) assets and gives you the ability to analyse the acquired data. The in-depth analysis of the trending information delivered by the ICMmonitor enables you to detect defects in an early state and prevent costly failures.

The ICMmonitor combines three devices into one instrument: A spectrum analyser, an acoustic detector, and a partial discharge (PD) monitor. The combination of spectrum analyser and PD detector greatly expands the measurement possibilities when analysing the insulation systems in a noisy environment. Thus, the ICMmonitor offers continuous PD on-line monitoring and excellent measurement results, even with a large amount of electrical noise.

With the monitoring web server function (MWS) you can remotely access the ICMmonitor instrument and see topical information on your asset’s condition. Additionally, you can receive an email notification in the case of system errors.

The ICMmonitor can be used for monitoring the following assets:

- Power transformers

- Motors

- Generators

- Cable systems

Standard features of the ICMmonitor are:

- PD spectrum analysis for the selection of frequency bands with less disturbances, resulting in an improved signal-to-noise ratio.

- A built-in four-channel multiplexer offers scanning of three-phase systems or multiple sensors, with each measurement channel separately configurable.

- Effective noise gating for blocking phase-stable or phase-independent noises

- Automatic data acquisition and storing for trend analysis, alarming, and reporting

- UHF measurements

The instrument is available with a wide range of optional features, giving it flexible installation and a range of configuration options that can meet your specific need.

Available features are:

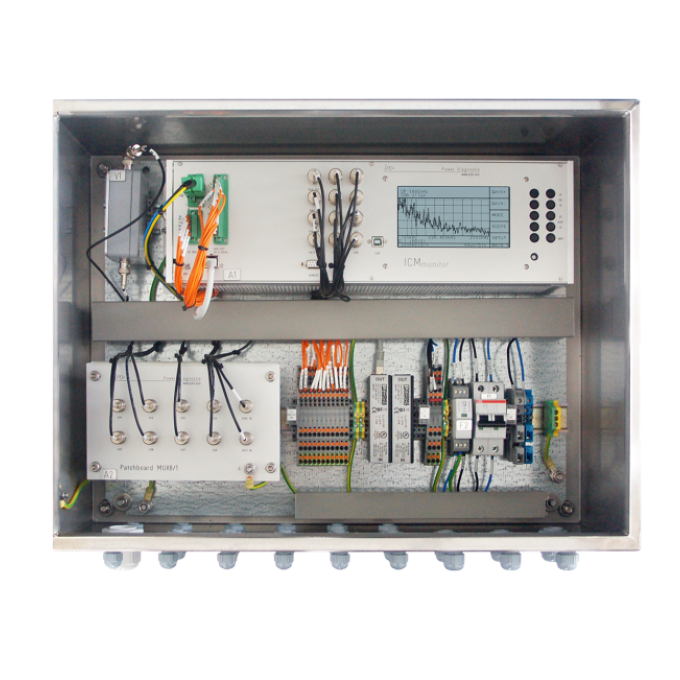

- Industrial monitoring cabinet with necessary supply and safety components pre-installed, suitable for outdoor installation

- Specialised control software for remote access and download of stored trending data.

- Eight-channel multiplexer.

- Monitoring web server for web browser based remote access and control from everywhere in your network.

- Mobile communication interface for remote access via UMTS

- Up to four additional output signals for external monitoring purposes.

- Up to six additional inputs for sensor signals.

- IEC 61850 interface.

- Built-in preamplifier.

- Pre-installed control PCs or notebooks.

- Expert software for PD pattern classification according to their PD faults.

Power Diagnostix’s ICMmonitor is equipped with a serial computer interface for the download of trending data and remote access, e.g., by LAN network (TCP/IP) or USB. Special software allows the remote control of the instrument, data evaluation, and in-depth diagnosis of the acquired data. This service software provides easy access to view, compare, and analyse the stored data.

Additionally, the optional monitoring web server (MWS) provides an Ethernet gateway for a platform-independent remote access to monitoring data recorded with the ICMmonitor. Alarms triggered by the instrument can be reported by automated email to the responsible person.

Combined with an LTE mobile router, a secure remote access via the Internet can be provided.

FAQ / Frequently Asked Questions

Medium and high voltage assets, such as power transformer, cable systems, and generators, are of high importance for every grid. With high electric fields in comparatively small spaces, failure can lead to extensive damage and long outages. PD monitoring with the ICMmonitor can help to keep these units in service for longer by early identification of insulation defects and efficient planning of maintenance or repair work. Thus, PD monitoring can prevent costly asset breakdowns and system failures.

The IEC 60270 standard covers the measurement of partial discharges (PD) occurring in electrical equipment, components, or insulation systems when tested with AC voltages up to 400 Hz or with DC voltage. It specifies requirements for the measurement equipment and for calibrators that should be used for measuring. Additionally, it defines three possible measurement setups to ensure reproducible and comparable PD measurement results.Power Diagnostix’s ICMmonitor meets all the requirements of the standard and thus guarantees highly accurate and reliable measurement results.

Observing the frequency spectrum of a harshly disturbed partial discharge signal allows to select frequency bands with fewer disturbances. Using such a selected frequency for a partial discharge acquisition, gives a largely improved signal-to-noise ratio resulting in a clear pattern acquisition. The combination of spectrum analyzer and PD detector within one instrument opens a broad field of new possibilities when analyzing isolation defects even with large noise.

Power Diagnostix offers a broad range of PD coupling units, cables, and other accessories to cover most of the possible monitoring situations with the ICMmonitor. Please refer to Power Diagnostix’s accessories catalogue for further information.

Further reading and webinars

Troubleshooting

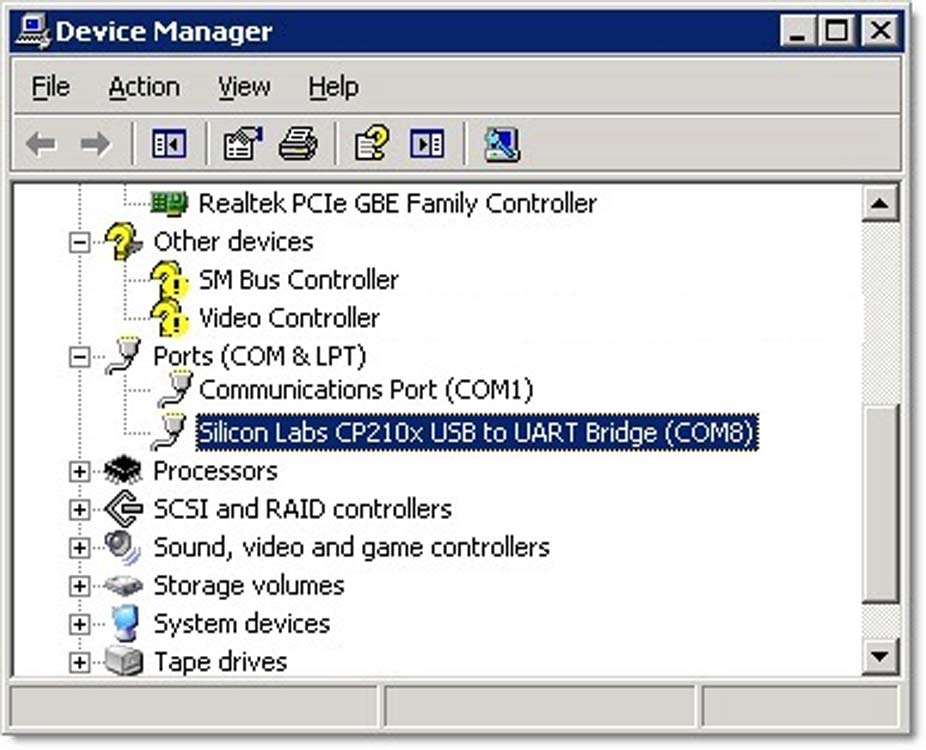

In the Windows Device Manager if the USB driver is properly installed.

If the automatic installation of the USB driver fails, it's possible to install the driver manually. Manual installation is divided into two steps due to the driver properties:

Step 1: Open the Windows Device Manager. Select “Silicon Labs CP210X USB to UART Bridge”, which is listed as an item of “Other devices”. Right-click on it and select “Update Driver” from the context menu.

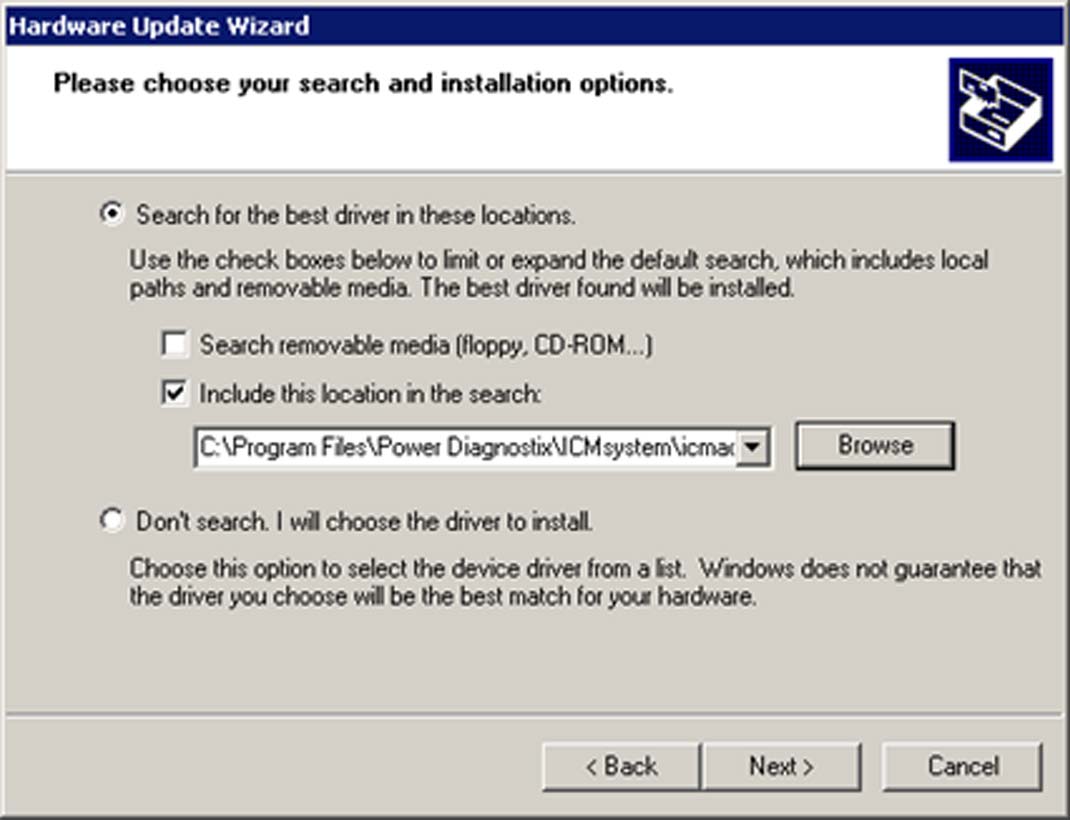

The “Hardware Update Wizard” will open. Select “Search for the best driver in these locations” and specify the directory, where the ICMmonitor software has been installed, as shown in the figure above. Click “Next” to proceed. Windows will now install the first part of the driver software, the USB controller driver:

Usually, the installation will end with an error message, since the second part of the driver – the USB bridge driver – is still missing. Repeat the steps above to install the second part of the CP210X bridge driver. If the installation is completed successfully, the CP210X device should appear in the “Device Manager”.

On PCs running Windows 10 with the Creator’s Update (2017) the ICMmonitor application window may appear very small on high resolution monitors. To enlarge the display size of the software, please take the following steps:

- Right-click on the application short cut on the desktop.

- Choose "Properties" from the context menu. This will open the “Properties” window.

- On the “Compatibility” tab, enable “Override high DPI scaling behaviour” and set “Scaling performed by” to “System”.

- If you have administrator rights, you can change the settings for all users by clicking the corresponding button.

- Approve the change by clicking “OK”.

The preamplifier must be enabled if an RPA is connected. Ensure that “>RPA ON” is marked in the instrument menu.

If this fails to resolve the issue, try substituting the BNC cables to be sure that the problem is not in the cables themselves. Replace the cables if they are faulty.

If the cables are not the issue, please contact our technical support team to discuss the next troubleshooting steps.

- First check that the calibrator is still on. The calibrator will shut off automatically after about 15 minutes without having one of its buttons pushed. Check that the low battery indicator is not visible on the LCD of the calibrator.

- The calibration pulse setting might be too weak for the test setup. Try increasing the magnitude of the calibration impulse applied to the test setup.

- The calibration pulse on-screen might be present but too small to be easily visible. Try putting the ICMmonitor into “NORM” mode Menu: SCOPE ► MODE ► NORM). This will make the calibration pulse appear as a vertical bar, which makes it easier to see on-screen that it appears in the “HOLD” mode.

- Sometimes the calibration pulse is lost if the high voltage power supply is connected to the test setup when the calibration is performed, even if the high voltage supply is completely powered off. Ensure that the power supply is not earthed during calibration. Try physically disconnecting the high voltage supply from the test object during the calibration process. The calibrator is then only connected via the quadrupole of the test object and the coupling capacitor (if present).

Interpreting test results

The evaluation of a PRPD pattern enables you to determine the kind of fault within the test object. Most partial discharge (PD) faults, such as insulation damages, voids, surface discharges, or floating points will have a completely different PD pattern.

The typical criteria used to classify these patterns are:

- Phase position of the maximum PD

- Phase position of the starting electron

- The gradient of discharges

- The shape of discharges in the positive and negative half-cycle

- The absolute value of discharge in pC or nC

- Short-time or continuous discharges

For successful interpretation, it is also necessary to get as much information as possible about the test object and its environment. Such information can be, for example, temperature, installation condition, age of the test object, previous faults, or weather conditions. It is useful to store typical PD patterns of known faults in an archive, which can be done by using Power Diagnostix’s ICMmonitor software. This customer-specific database will be helpful for later evaluation on other test objects.

User guides and documents

FAQ / Frequently Asked Questions

The ICMmonitor features various noise handling techniques to cope with disturbance signals, depending on their level, nature, and source. The instrument’s noise gating module can be connected to an antenna or a current transformer to sense and remove noise in an environment with high frequency (HF) disturbances, such as radar signals, corona discharge, or a thyristor firing, without losing significant partial discharge (PD) data. A noise level that is stable over the whole phase can be removed from the PD pattern by the low level discriminator (LLD) function. Additionally, an appropriate choice of external preamplifiers can limit PD acquisition to a frequency band with less background noise. The optional ICMmonitor control software also provides you with another method simple windowing, that suppresses phase-stable pulses occurring in the defined windows.

Often, the high voltage applied to the test setup is not in phase with the line voltage and may not even be the same frequency as the line voltage. In such cases, it is best to synchronise each channel of the ICMmonitor with an external signal which is usually derived from the coupling unit but can also be taken from an extra voltage divider. Nevertheless, in the absence of an external synchronisation signal, the ICMmonitor automatically synchronises with the frequency of the line voltage of its supplying power (usually 50 or 60 Hz). Therefore, an external synchronisation signal is not mandatory but recommended.

The ICMmonitor does not need any calibration, nor does it require any maintenance on a regular basis, as the PD measurement is a relative measurement that is calibrated with a reference source prior to a measurement being taken. The calibration impulse generator as the reference source, however, should be calibrated on an annual basis to ensure that its output signal remains within the recommended boundaries.